- What is a process engineer?

- What does a process engineer at an energy company do?

- Process engineer salary and benefits

- Process engineer skills and requirements

- Responsibilities of a process engineer

- Locations of process engineer jobs

- Challenges in process engineering

- Career progression and growth opportunities

- Work environment and culture

- How to Become a process engineer in the Energy Industry

- Benefits of working a process engineer

What is a process engineer?

A process engineer designs, optimizes, and oversees production processes in manufacturing or chemical plants. They ensure that equipment and workflows maximize efficiency, minimize waste, and meet safety and quality standards. As a process engineer, your work often involves analyzing processes, troubleshooting issues, and implementing improvements to enhance productivity while ensuring compliance with regulatory requirements and environmental standards.

What does a process engineer at an energy company do?

Some of the most common tasks of a process engineer at an energy company are: designing and optimising processes for the production and distribution of energy. They ensure efficient, safe, and cost-effective operation by analyzing workflows, managing equipment, and troubleshooting production issues. A process engineer’s role includes reducing waste, improving productivity, and ensuring compliance with environmental and safety standards to enhance overall energy generation and distribution.

Process engineer salary and benefits

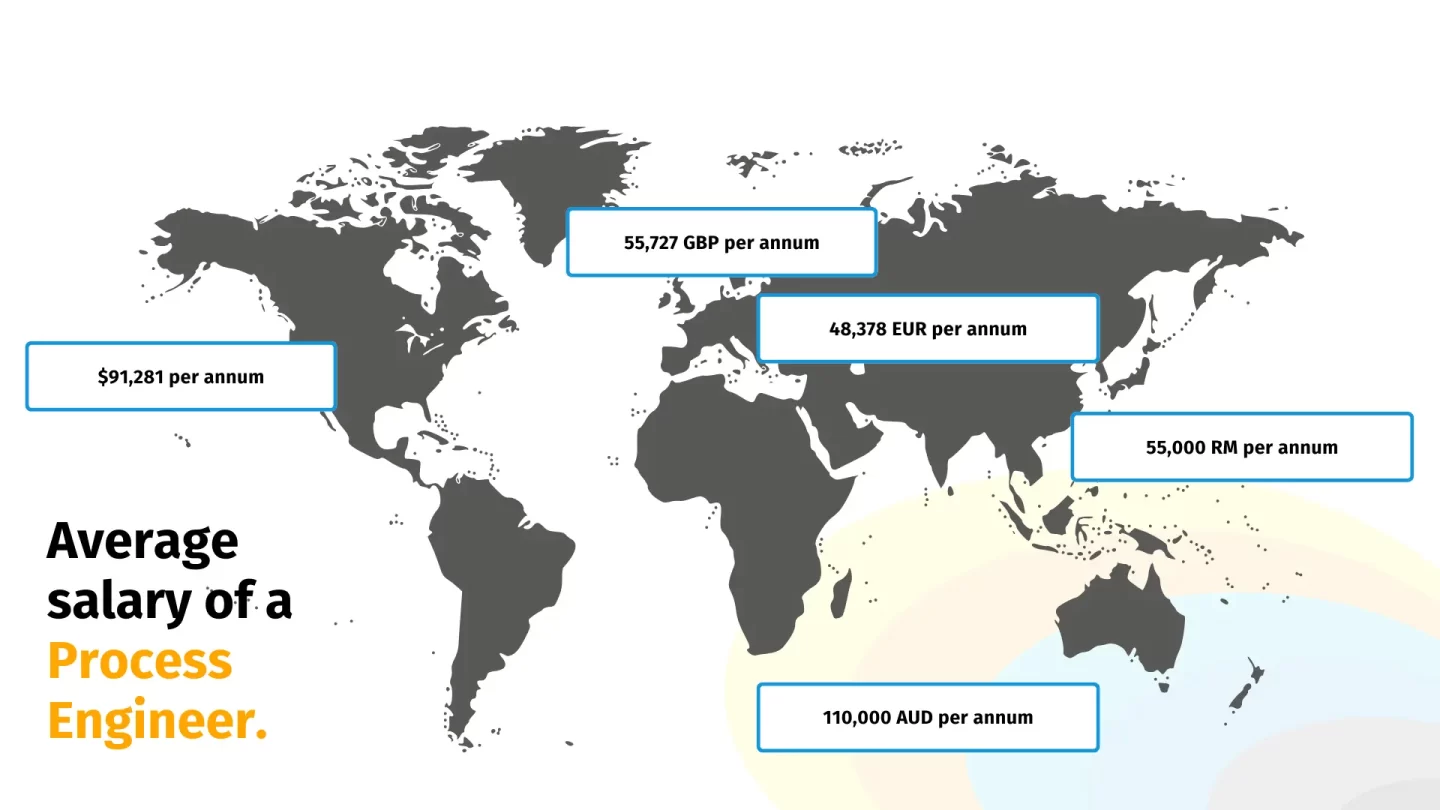

The salary and benefits for a process engineer can vary widely depending on several factors such as the industry, geographic location, level of experience, and the specific nature of the contract.

For example, according to Payscale, the average salary for a process engineer in The Netherlands is 48,378 EUR as of 2024. On the other hand, those working in the USA, earn an average of 91,281 USD. If we go to Australia, you can expect to bring home around 100,000 to 120,000 AUD, according to seek.com.au. This same website indicates that the average salary range in Malaysia goes from 49.4K to 65K RM. Finally, a process engineer from the UK can earn 55,727 GBP on average.

Working as a process engineer offers diverse benefits, including competitive salaries and strong job stability due to demand across various industries. Engineers engage in problem-solving and innovation daily, providing intellectual challenges and growth opportunities. They can specialize in sectors like energy or pharmaceuticals, offering career flexibility. Additionally, involvement in efficiency and sustainability initiatives gives a sense of purpose, while collaboration with interdisciplinary teams fosters a supportive, knowledge-sharing work environment.

Process engineer skills and requirements

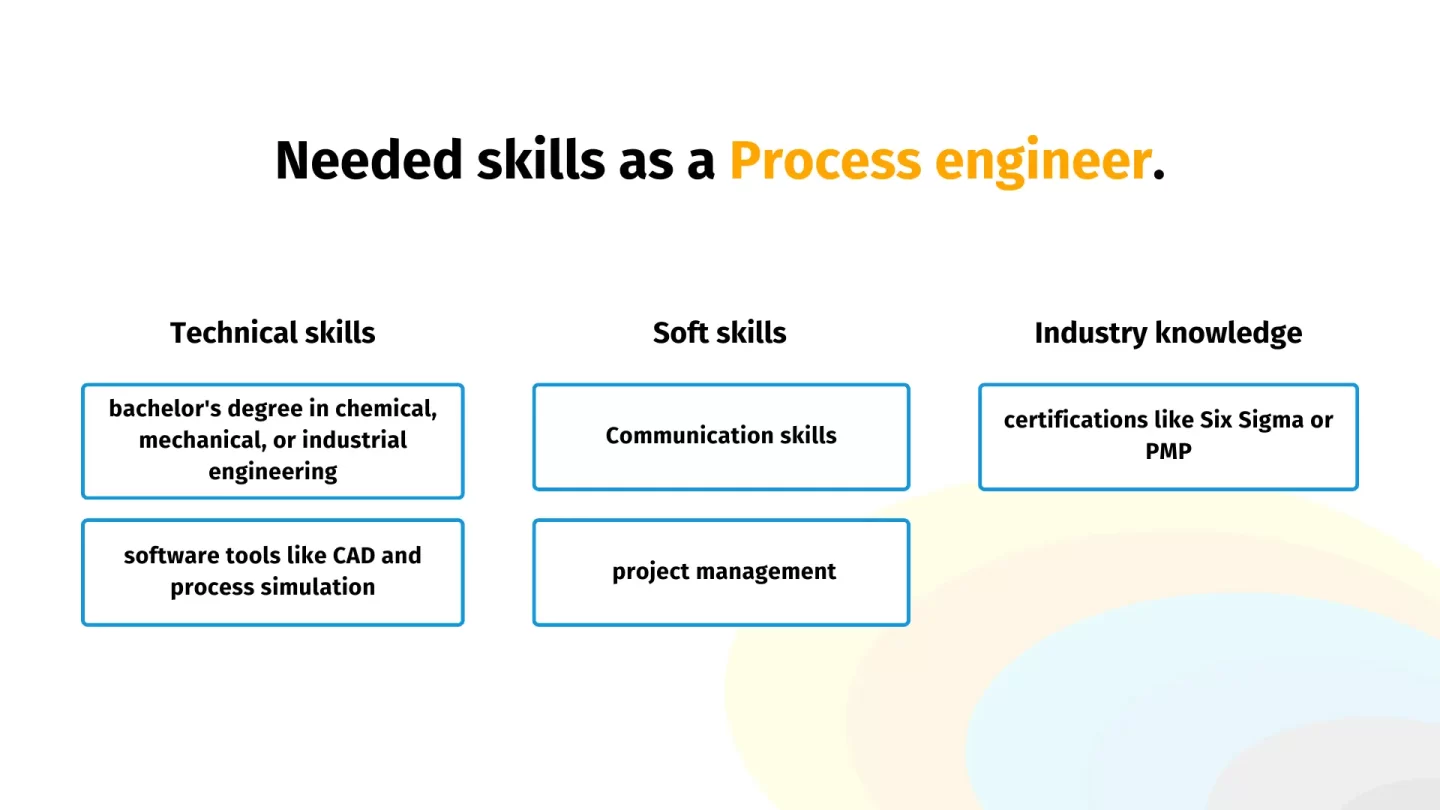

In order to hold a position, process engineers should possess strong analytical and problem-solving skills to design and optimize production workflows. Technical proficiency in CAD software and process simulation tools is essential, as is a deep understanding of process control principles. They must be adept at project management, able to coordinate multiple projects while ensuring compliance with safety and environmental regulations. Effective communication skills are crucial for collaboration with cross-functional teams, while creativity aids in troubleshooting and developing innovative process improvements.

Educational requirements typically include a bachelor’s degree in chemical, mechanical, or industrial engineering, with certifications like Six Sigma or PMP providing a competitive edge.

Responsibilities of a process engineer

Some of the expected responsibilities for a process engineer are designing, analyzing, and optimizing production processes to ensure efficient and cost-effective operations. You will develop detailed process designs, selects appropriate equipment, and creates plans for installing and configuring new systems. They also troubleshoot existing workflows to identify and resolve inefficiencies or quality issues. In collaboration with cross-functional teams, a process engineer develops and implements strategies that align with safety, quality, and regulatory standards.

Process engineers continually monitor and analyze process data, using insights to recommend improvements. They also oversee the commissioning of new equipment, train operators, and document changes to maintain compliance and support future optimizations.

Locations of process engineer jobs

Process engineer jobs are commonly found in regions with significant manufacturing or energy sectors. Industrial hubs like Texas and Louisiana in the U.S. offer roles in petrochemicals and oil refining. Europe has strong opportunities in Germany, the Netherlands, and the UK. Asian countries like China and India also feature robust manufacturing and energy sectors. Renewable energy-focused roles are growing globally, particularly in countries like Germany, Australia, and the United States.

Challenges in process engineering

Many challenges are in store for a process engineer due to the nature of their position. Ensuring safety and compliance amid strict environmental regulations while optimizing production efficiency is one of them. Process engineers must manage equipment failures, handle unpredictable raw material costs, and navigate labor shortages. Additionally, adapting to emerging technologies like automation and sustainable practices requires ongoing skill development. Balancing these complexities demands innovative problem-solving and strategic planning to maintain productivity while minimizing environmental and operational risks.

Career progression and growth opportunities

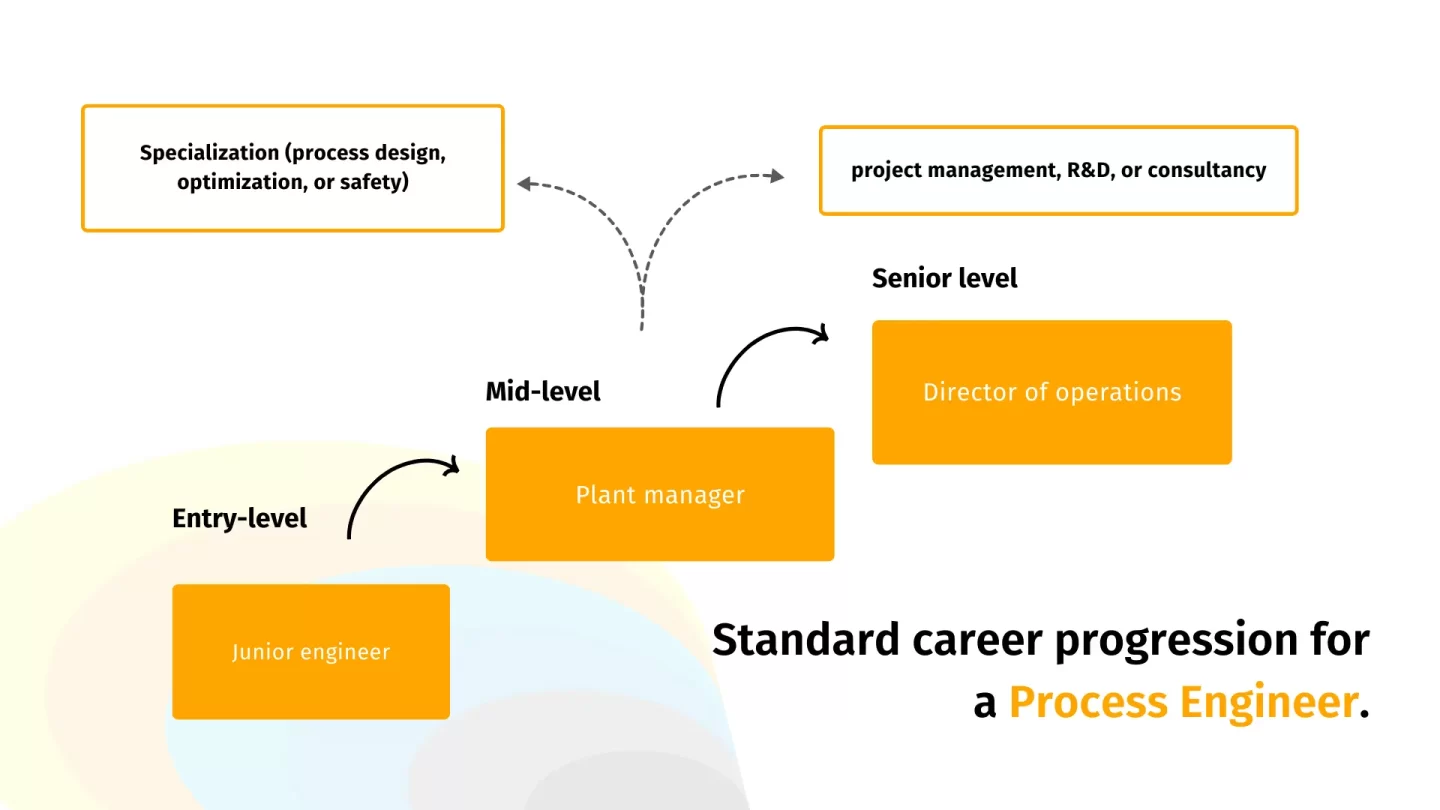

Process engineering offers diverse career progression opportunities, from junior engineer roles to leadership positions like plant manager or director of operations. Engineers can specialize in niches like process design, optimization, or safety, and gain certifications like Six Sigma or PMP for advancement. Transitioning into project management, R&D, or consultancy provides further growth. Continuous learning, technical expertise, and strategic skills can unlock leadership roles, ensuring dynamic career paths within various industries.

Work environment and culture

The work environment for process engineers is dynamic, blending office and field work. In the office, they analyze data, develop process designs, and collaborate with interdisciplinary teams to plan and optimize production workflows. On-site, as a process engineer, they monitor equipment, troubleshoot issues, and oversee process improvements, often requiring safety gear in high-risk environments. The culture emphasizes safety, compliance, and teamwork, given the complexities of balancing productivity and regulatory standards. Engineers often work with operators, managers, and other specialists, fostering a culture of continuous improvement and innovation. Flexibility, adaptability, and strong communication are key, as projects evolve and require cross-departmental collaboration.

How to Become a process engineer in the Energy Industry

Some factors to consider when looking to become a process engineer in the energy industry are the need to earn a bachelor’s degree in chemical, mechanical, or industrial engineering. This degree should focus on coursework related to thermodynamics, fluid dynamics, and process design. Internships or co-op programs in energy companies provide valuable hands-on experience. Enhance skills by learning relevant software tools like CAD and process simulation. Pursue certifications such as Six Sigma or PMP for a competitive edge.

Build expertise in safety regulations and environmental compliance through specialized courses. Networking and professional associations help discover opportunities, while entry-level roles offer practical industry exposure and pave the way for growth and specialization.

Benefits of working a process engineer

Working as a process engineer offers numerous benefits. The role provides:

Job stability due to high demand across industries like oil and gas, manufacturing, and renewable energy

It is intellectually stimulating, requiring innovative problem-solving to optimize production while meeting regulatory standards.

Competitive salaries and comprehensive benefits make it financially rewarding. You can specialize in niche areas, allowing for career flexibility and advancement.

Opportunities for continual learning and professional development are abundant, especially as emerging technologies reshape the field. Collaboration with interdisciplinary teams creates a dynamic work culture, while contributions to safety and efficiency deliver personal and societal fulfilment.

Drawbacks

Process engineering has challenges like managing high-pressure projects with tight deadlines, leading to potential stress. Navigating complex safety regulations and ensuring compliance adds to the workload. Engineers often balance office tasks with fieldwork in potentially hazardous environments. Additionally, troubleshooting production issues can require irregular hours. Rapid technological changes demand continuous learning, and global economic shifts can create job uncertainty in certain industries, making adaptability crucial.

Current process engineer jobs

WTS Energy offers positions requiring strong engineering backgrounds, with responsibilities like optimizing project execution, compliance, and safety. Check out our jobs by clicking on the button below or here.